Annual Report 2016 25

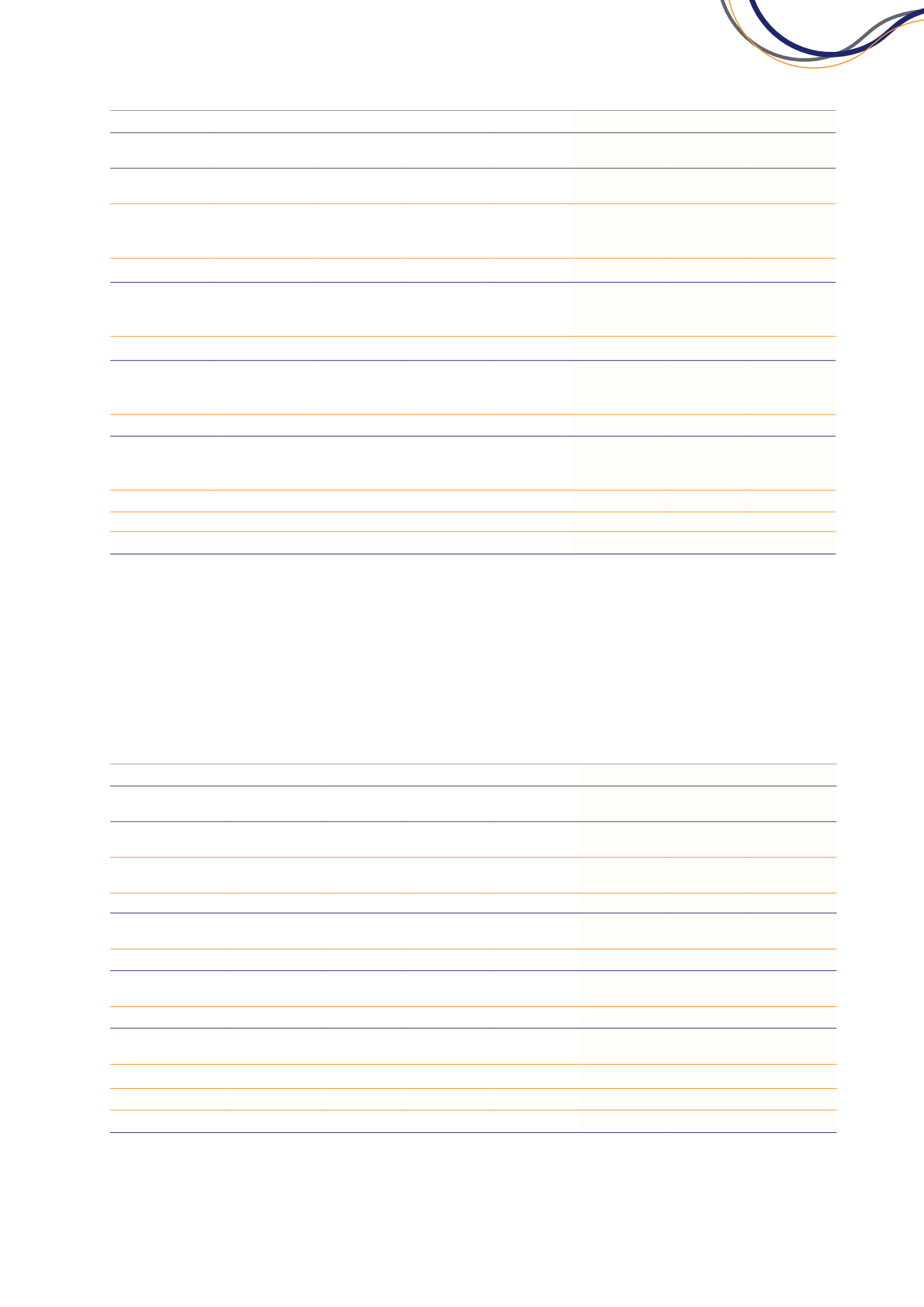

Table 5: Long Operation – June 2016 Mineral Resources (and 2015 comparison)

Mineral Resources - 30 June 2015

Mineral Resources - 30 June 2016

Tonnes

Grade

Contained

Metal

Tonnes

Grade

Contained

Metal

Classification

(t)

Ni

(%)

Ni

(t)

(t)

Ni

(%)

Ni

(t)

Long

Measured

65,000

5.4

3,500

62,000

5.3

3,300

Indicated

287,000

5.1

14,600

287,000

5.1

14,600

Inferred

355,000

4.7

16,700

355,000

4.7

16,700

Sub-Total

707,000

4.9

34,800

704,000

4.9

34,600

Victor South

Measured

-

-

-

-

-

-

Indicated

147,000

2.1

3,100

147,000

2.1

3,100

Inferred

33,000

1.5

500

33,000

1.5

500

Sub-Total

180,000

2.0

3,600

180,000

2.0

3,600

McLeay

Measured

63,000

6.3

4,000

61,000

6.4

3,900

Indicated

71,000

4.9

3,500

71,000

4.9

3,500

Inferred

21,000

6.7

1,400

21,000

6.7

1,400

Sub-Total

155,000

5.7

8,900

153,000

5.8

8,800

Moran

Measured

234,000

6.6

15,500

126,000

7.2

9,100

Indicated

51,000

3.3

1,700

44,000

3.9

1,700

Inferred

52,000

3.7

1,900

52,000

3.7

1,900

Sub-Total

337,000

5.7

19,100

222,000

5.7

12,700

Stockpiles

Measured

-

-

-

-

-

-

GRAND TOTAL

1,379,000

4.8

66,400

1,259,000

4.7

59,700

Notes:

1.

Mineral Resources are reported using a 1% Ni cut-off grade except for the Victor South disseminated Mineral Resource, which is reported

using a cut-off grade of 0.6% Ni.

2.

Block modelling used the ordinary-kriging grade-interpolation method on 1m composites within wireframes for all elements and density for

the Victor South, McLeay and Moran deposits. For the Long mineralisation, ordinary-kriging was used to estimate metal accumulation and

horizontal width variables for each drill hole intercept into a two-dimensional block model. The final block grades were back-calculated and

the block model was converted to a conventional three-dimensional block model using nearest neighbour assignment.

3.

Mining as at 30 June 2016 has been removed from the 2016 Mineral Resource estimate.

4.

Mineral Resources are inclusive of Ore Reserves.

5.

All figures are rounded to reflect appropriate levels of confidence. Apparent difference may occur due to rounding.

6.

JORC Code (2012) Table 1 Parameters are contained within IGO’s 2016 ASX Resources and Reserves Statement as released to the ASX which

can be found at

www.igo.com.auTable 6: Long Operation – June 2016 Ore Reserves (and 2015 comparison)

Ore Reserves - 30 June 2015

Ore Reserves - 30 June 2016

Tonnes

Grade

Contained

Metal

Tonnes

Grade

Contained

Metal

Classification

(t)

Ni

(%)

Ni

(t)

(t)

Ni

(%)

Ni

(t)

Long

Proved

28,000

3.6

1,000

23,000

3.5

800

Probable

94,000

2.8

2,600

45,000

3.1

1,400

Sub-Total

122,000

3.0

3,600

68,000

3.2

2,200

Victor South

Proved

7,000

3.0

200

4,000

5.0

200

Probable

15,000

2.2

300

6,000

1.7

100

Sub-Total

22,000

2.5

500

10,000

3.0

300

McLeay

Proved

22,000

3.5

800

18,000

3.9

700

Probable

24,000

3.1

700

19,000

3.2

600

Sub-Total

46,000

3.3

1,500

37,000

3.5

1,300

Moran

Proved

380,000

4.0

15,200

224,000

4.2

9,400

Probable

38,000

3.0

1,200

12,000

3.3

400

Sub-Total

418,000

3.9

16,400

236,000

4.2

9,800

Stockpiles

Proved

-

-

-

-

-

-

GRAND TOTAL

608,000

3.6

22,000

351,000

3.9

13,600

Notes:

1.

Ore Reserves are reported above an economic Ni Cut-off value as at 30 June 2016.

2.

A NSR value of $176/t has been used in the evaluation of the 2016 Ore Reserve.

3.

Mining as at 30 June 2016 has been depleted from the 2016 Ore Reserve estimate.

4.

All figures are rounded to reflect appropriate levels of confidence. Apparent difference may occur due to rounding.

5.

Revenue factor inputs (US$): Ni $11,766/t, Cu $5,173/t. Exchange rate A$1.00 : US$0.74.

6.

JORC Code (2012) Table 1 Parameters are contained within IGO’s 2016 ASX Resources and Reserves Statement as released to the ASX which

can be found at

www.igo.com.au