Sustainability Report 2015 37

BACKGROUND

The Jaguar Operation comprises approximately

395.4 square kilometres of tenements. The area has

historically hosted three economically viable underground

mines; the first discovered was the Teutonic Bore. The

Jaguar deposit was discovered in 2002 approximately 4km

south of the Teutonic Bore and the most recent discovery,

the Bentley deposit, was discovered in 2008.

The Jaguar Operation was acquired by IGO as part of the

takeover of Jabiru Metals Limited in 2011. The Operation

now consists of the nearby Bentley zinc-copper-silver-

gold underground mine, the Jaguar processing facility,

administration infrastructure, and the accommodation

village. Operations in the Jaguar underground mine

ended at the start of FY2014, and, as a result, all FY2015

mill production ore is expected to be sourced from the

Bentley deposit.

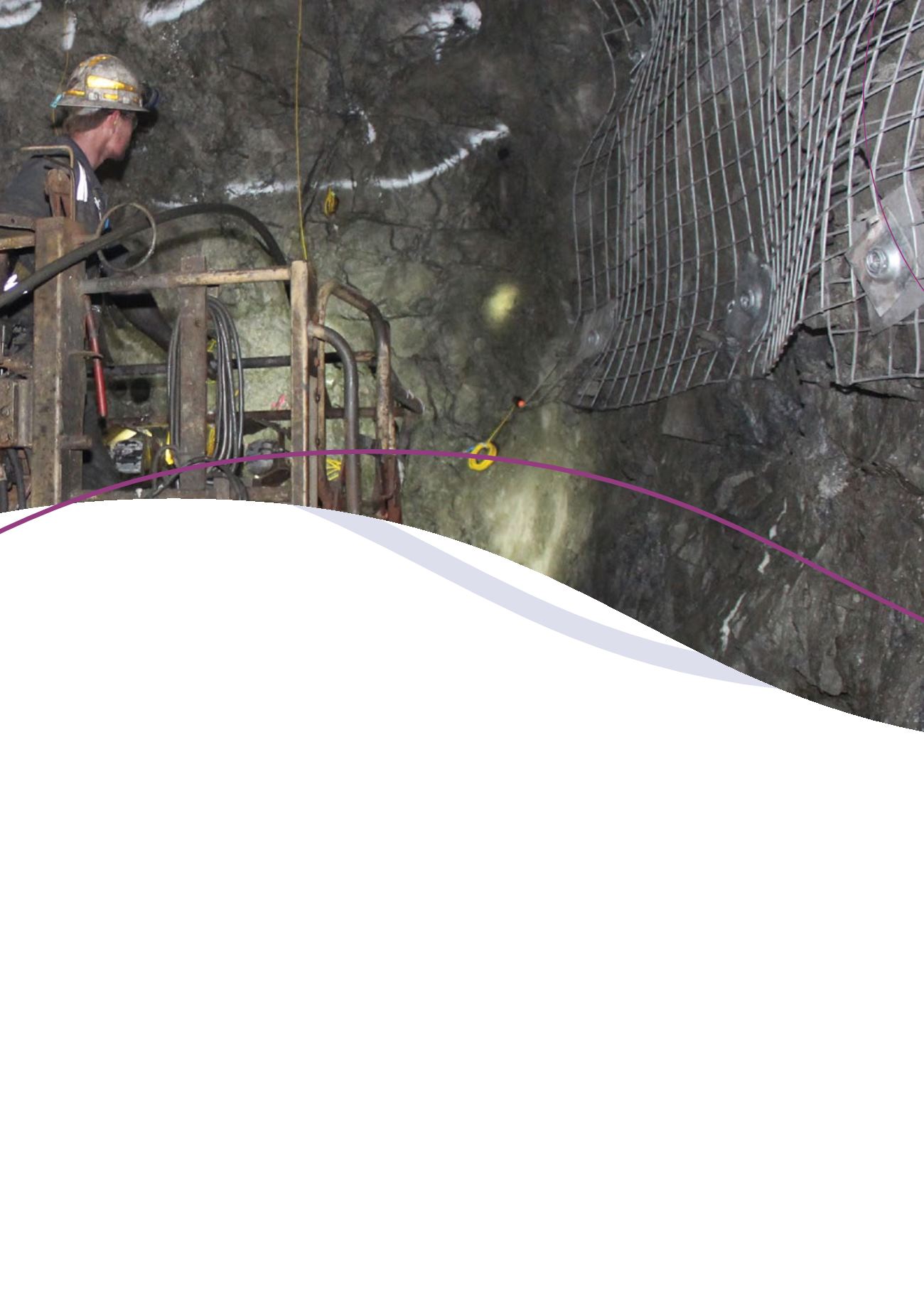

IGO’s operations involve the underground mining of

ore and waste rock. Traditional stope mining methods

are employed. Ore is processed on site at a nominal

rate of 450 to 480 ktpa. The processing plant has been

designed to recover copper and zinc by ore crushing,

milling, classification, flotation, thickening, and concentrate

filtration.

The plant produces a saleable copper sulphide product

containing 25 to 28% copper and zinc sulphide product

containing 48 to 50% zinc. Additionally, IGO receives

credits for the silver and gold that is incidentally captured

in our concentrates.

Once filtered the concentrate contains about 10%

moisture. Copper and zinc concentrates are packaged into

sealed sea containers and transported 720km from site to

Geraldton Port for export.

Jaguar’s workforce is predominantly FIFO with some

employees drive-in drive-out.

In FY2015, the Jaguar Operation produced a total of

485,302 tonnes of ore exclusively from the Bentley

underground mine which produced 93,093 tonnes of Zinc

concentrate and 28,936 tonnes of copper concentrate.

The mining process at the Jaguar Operation results in the

creation of underground voids. Where the surrounding

rock is also to be mined, these voids must be backfilled to

prevent the collapse of the new mining areas. At Jaguar

this is achieved by backfilling voids with waste rock and

cement aggregate fill (CAF).

At present, exploration activity at Jaguar is carried out

from both underground and surface drill sites.

The Jaguar Operation has required the clearance of

342 ha of natural bush to date.

OPERATIONS