Downstream Processing

Downstream Processing

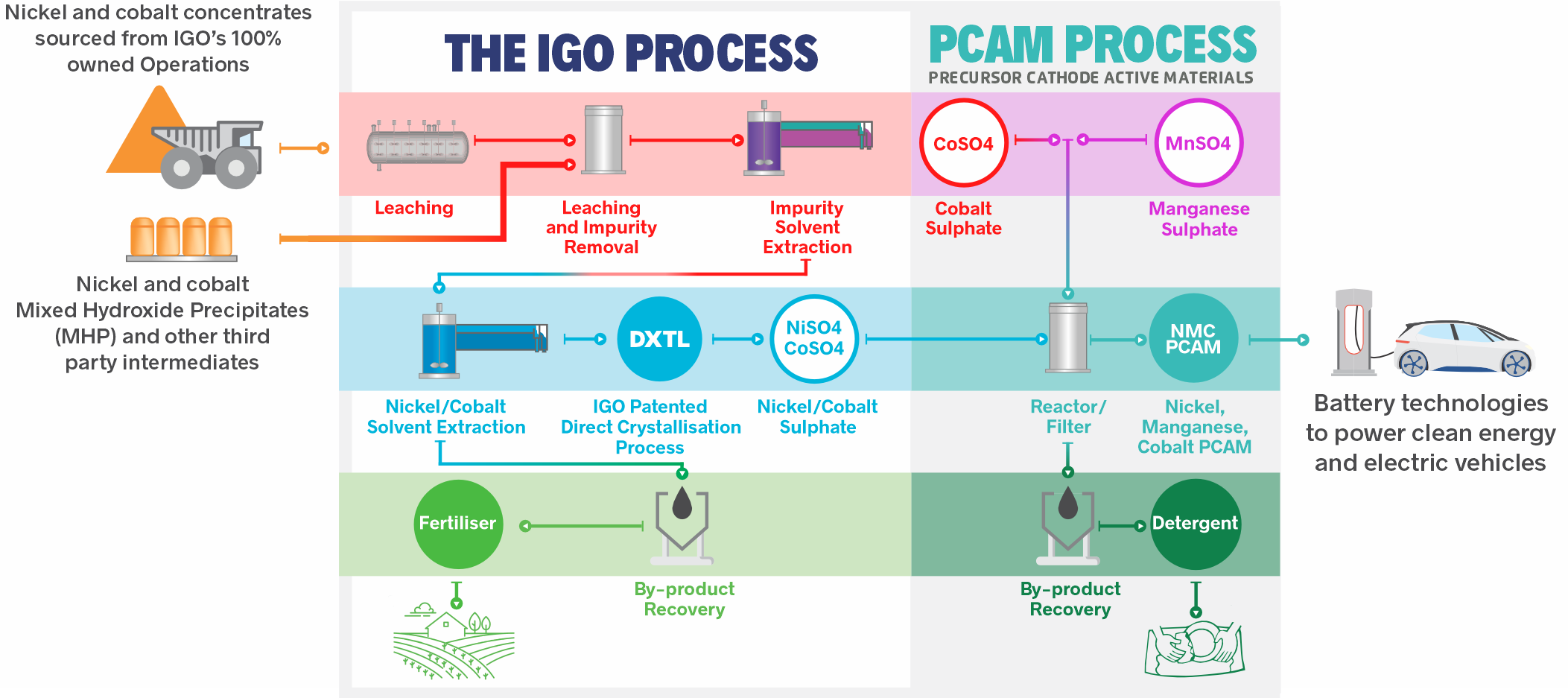

IGO Limited, in conjunction with metals and mining business Wyloo Metals (Wyloo), is exploring the development of a project to produce cathode precursor for the lithium-ion battery industry.

As part of our strategy to connect with end users via vertical integration, the project involves combining a downstream nickel refinery with a plant producing precursor cathode active material (PCAM) that would bring together IGO’s disruptive nickel refining technology with battery precursor production expertise.

The proposed Integrated Battery Material Facility (IBMF) would harness the IGO Process™ that has been proven to produce nickel rich battery grade chemicals at a lower cost and lower carbon emissions when compared with traditional processes for nickel sulphide concentrates.

Combining the IGO Process™ with leading precursor manufacturing technology, the proposed IBMF would produce PCAM needed for the manufacture of nickel rich cathode material for lithium-ion batteries.

The Western Australian Government recently allocated approximately 30 hectares in the Kwinana-Rockingham Strategic Industrial Area for IGO and Wyloo’s IBMF. Read more in the ASX Announcement: Land Secured at Kwinana for Proposed Integrated Battery Material Facility. The land is located on the Gnaala Karla Booja region of the Noongar Nation. IGO acknowledges the connection of the Noongar people to that Country and their Elders, past, present and emerging.

Proposed integrated battery material facility at Kwinana: Conceptual render

Proposed integrated battery material facility at Kwinana: Conceptual render

Battery Supply Chain and Vertical Integration

Globally, the increasing demand for electric vehicles and other green technologies is fuelling continued growth in the battery supply chain.

Lithium-ion batteries are essential to support our decarbonisation goals as we reduce our reliance on fossil fuels.

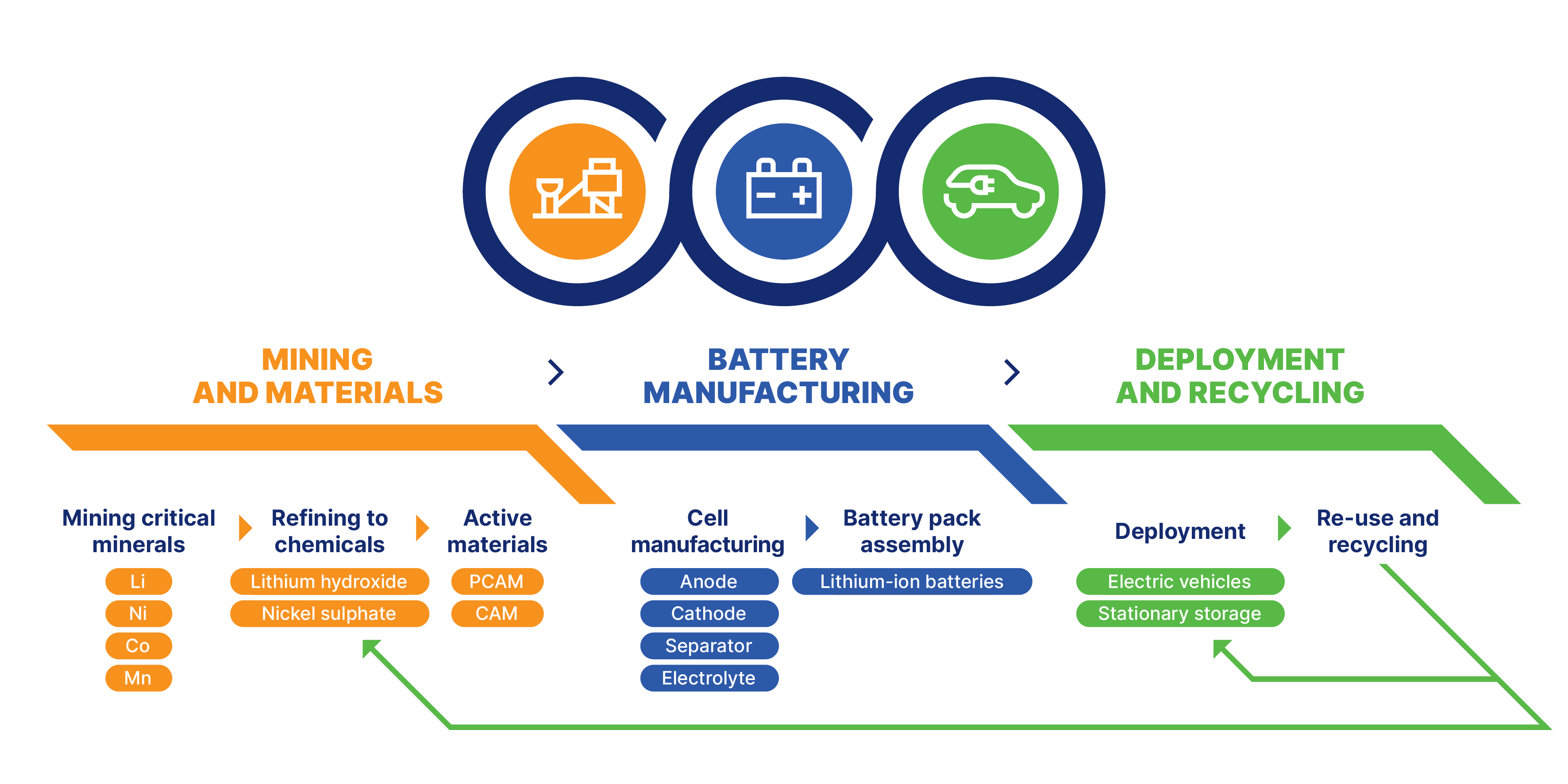

The battery supply chain refers to the integrated supply chain of processes and activities involved in the production, distribution and recycling of batteries, with a focus on lithium-ion batteries, and includes:

1. Raw material extraction, refining and active materials production

- Below ground, minerals bearing lithium, nickel, cobalt and manganese are the source of these essential metals needed for battery cell manufacturing, with Australia having globally significant mineral reserves

- These raw minerals are then processed and purified to produce specialty battery chemicals, such as nickel sulphate. The next step is the production of active material, such as PCAM.

2. Cell manufacturing and battery pack assembly

- In this stage active materials are combined to form anode and cathode materials, along with electrolytes and separators required for cell production

- These battery components are then assembled into battery cells, which are integrated in larger battery packs or modules.

3. Battery deployment and recycling

- Fully assembled battery packs are then distributed for installation in electric vehicles, electronic devices, etc.

- At the end of their life, batteries are then able to be recycled, used in stationary applications or broken down to recover the individual battery components and metals for reuse.

The IGO Process™ and PCAM

IGO developed and owns the IGO Process™, which is a low carbon footprint hydrometallurgical process for producing battery grade nickel sulphate. IGO has also completed extensive test work and studied a range of methods for processing nickel sulphate from intermediates.

In partnership with Wyloo, IGO is undertaking a feasibility study to assess opportunities for downstream processing of nickel concentrates and nickel intermediates to produce battery grade nickel sulphate within Australia.

The project would represent the first commercial production of PCAM in Australia and would align with the State Government’s efforts to support the growth of Western Australia’s battery industry.

IGO and Wyloo are currently advancing discussions with a global battery chemical manufacturer which has indicated strong interest in partnering in the project. This is an important step in integrating the parties’ technologies with IGO and Wyloo’s critical minerals to capture value across the supply chain.

Other key workstreams required before a final investment decision can be made include environmental permitting and approvals, broad stakeholder engagement and the achievement of key commercial outcomes.